contact information

Stéphane FOUILLOTCEO

contact details

Les Echerolles03150 SAINT-LOUP

Fax 04 70 47 46 90

stephane.fouillot@novaxess.fr

http://www.novaxess.fr

Machine-tool

presentation / know-how

More than 20 years experience in the field of chip evacuation and processing and the management of cutting fluids.

With a staff of 15 people and an annual turnover of 1.5 million euros, NOVAXESS TECHNOLOGY puts its expertise and experience at the disposal of its national and international customers in the field of metal chip evacuation and processing and the management of cutting fluids.

NOVAXESS TECHNOLOGY thanks to its ultra-specialised expertise can guide you in your very specific domain : the machine-tool by the machining or deformation of chips.

- Technical sales reps services

- In-house design department

- Show-room

- Work shops

- In an area of 1800m2

Defining the needs

· technical specifications, machine drawings, machine equipped with an existing conveyor or a machine non-equipped ….

· A technical visit, measurements taken on site, feasability study, analysis and then a technical proposition, price quote

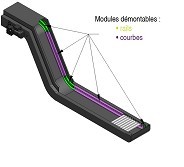

Design

· Realisation of an overall plan of the environment, of the machine … then we proceed to the design of the conveyor.

· Realisation of a plan in 3D, then single drawings directly to the cutting and bending machines

Manufacturing

The realisation of the whole processing system in our workshops : assembly, painting, controls and operational tests before delivery.

Click on the icon to download the document in PDF for this company.

-

MAGNETIC CONVEYORS

Our magnetic type conveyors with CONVAFLEX ® technology, ideal for small chips or 100% steel or iron parts

-

CONVEYORS - CONVAFLEX®

Our hinged steel belt chip conveyors with the CONVAFLEX ® technology are ideal for long and short chips.

-

SCRAPER CONVEYORS

Our scraper type conveyors using the technology CONVAFLEX®, are ideal for short and fractionated chips.

-

CENTRAFLEX ®

-

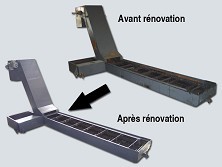

Spare parts for chip conveyors, maintenance, renovation and audits.

Whatever may be the make, the country of origin, the type of your convoyer (belt, scraper, chain driven, etc …), we have a reliable and economical technical solution to offer you.

-

Services in our work shops

Renovation, restoration, audit, modifications, adaptation... improvements on all kinds of conveyors.

Custom-mad manufacturing for all makes of conveyors : steel belts, the whole chain and scraper assembly, bars with magnets, worm screw etc...

Version française

With the support of Symop – the French Association for manufacturing Technologies - Privacy policy

Version française

With the support of Symop – the French Association for manufacturing Technologies - Privacy policy